Real-Time Manufacturing Intelligence

Selplast implements the PLAST 4.0 IIoT platform to provide a single source of truth for your entire manufacturing operation. We connect your equipment and digitize your processes to unlock real-time data, improving OEE and driving profitability.

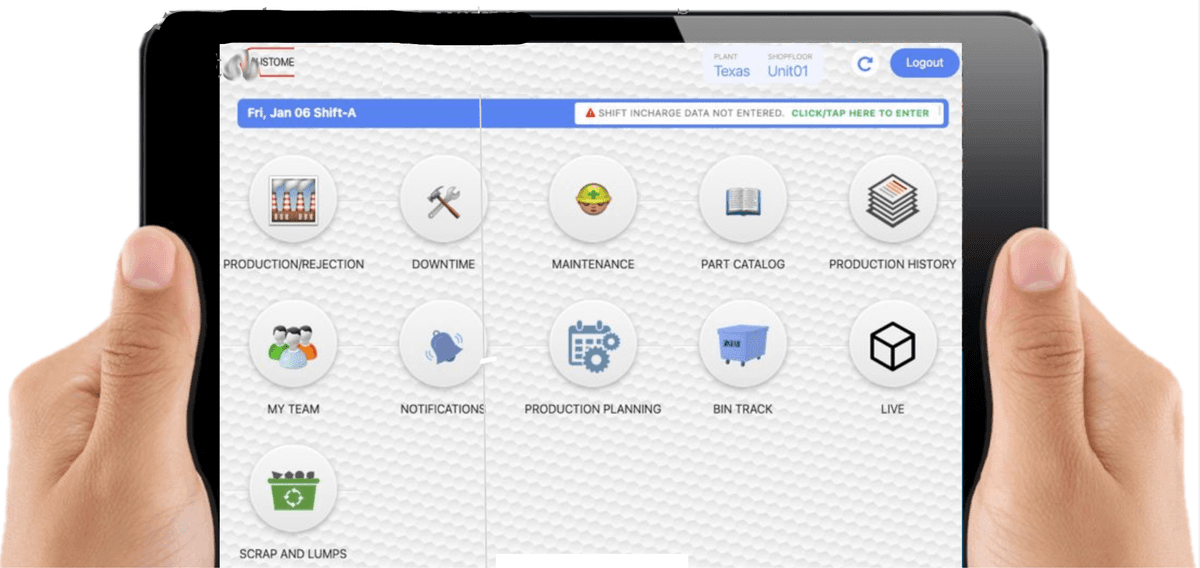

Centralized Command Center

The platform provides a complete, top-down view of your plant. The main dashboard offers at-a-glance access to production, maintenance, and planning modules, allowing for immediate operational awareness.

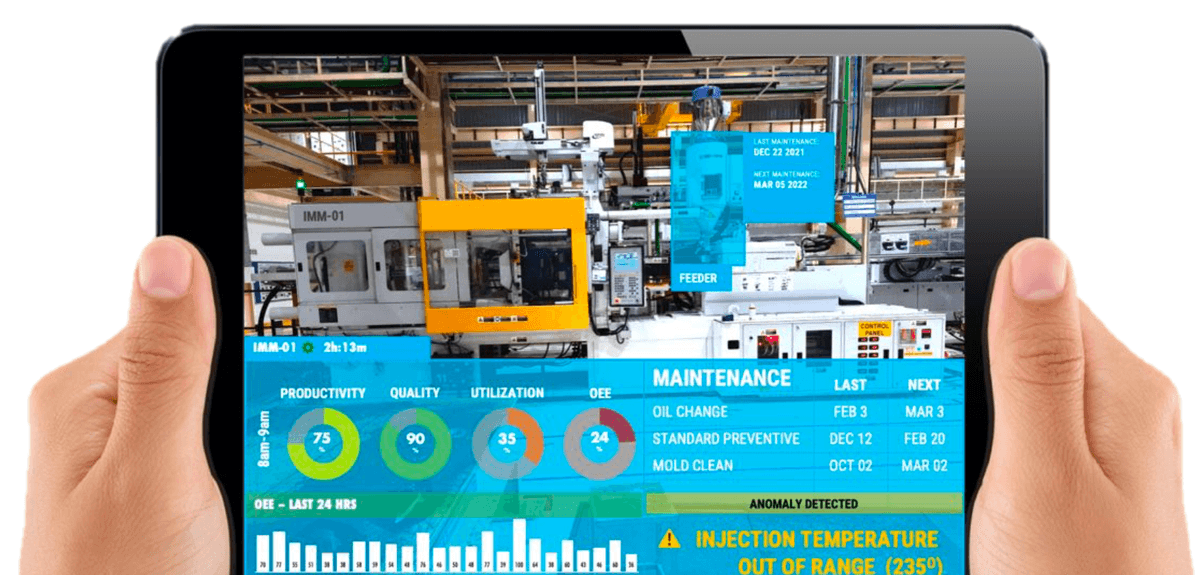

Drill-Down Analytics

Move beyond high-level KPIs. Drill down into any machine to view live and historical data for specific parameters, cycle times, alarm history, and rejection analysis, all without touching a paper logbook.

Measurable Performance Gains

By providing a single source of truth for all machine and operational data, the platform enables significant, tangible improvements to your bottom line.

Up to 40%

Downtime Reduction

Up to 30%

Productivity Improvement

Up to 20%

Energy Savings

Key System Capabilities

Visualize live OEE with detailed breakdowns, and track critical KPIs across all machines.

IoT modules connect directly to any machine, gathering critical data and eliminating manual entry.

Automate maintenance schedules based on machine runtime, shots, or condition-based monitoring.

Replace manual logbooks and ISO forms with a fully digital, user-friendly tablet interface.

Technical & Integration Capabilities

The platform is built on an open architecture, designed for seamless integration into existing manufacturing ecosystems.

Hardware Ecosystem

Includes a full suite of hardware from IoT gateways to edge computing hubs for robust, on-premise data processing.

Seamless ERP/SAP Integration

Automatically sync production data with your existing ERP or SAP systems, eliminating manual data entry and ensuring data consistency.

Industry Standard Protocols

Natively compliant with the OPC UA M2M protocol, with the flexibility to customize for other communication standards as required.

Proven & Tangible ROI

Our implementation strategy focuses on tangible gains, with most partners achieving a full return on investment in 12 to 18 months.